By rolling and nitriding processes, 0.23- to 0.3-mm-thick grain-oriented 6.5 wt% silicon steel sheets were produced. The core losses of grain-oriented 6.5 wt% silicon steel at frequencies ranging from 400 Hz to 20 kHz were lower than that of the grain-oriented 3 wt% silicon steel with the same thickness by 16.6-35.8%. The secondary recrystallization behavior was investigated by scanning electron microscopy, energy-dispersive spectroscopy, and electron backscattered diffraction. The results show that the secondary recrystallization in high-silicon steel sheets develops more completely as the nitrogen content increases after nitriding, secondary recrystallized grain sizes become larger, and the sharpness of Goss texture increases. Because more {110}⟨116⟩{110}⟨116⟩ grains in the subsurface and the central layer of the sheets have a lot of 20°-45° high-energy boundaries in addition to Goss grains, {110}⟨116⟩{110}⟨116⟩ can be the main component through selective growth during secondary recrystallization when the inhibitor quantity is not enough and inhibitor intensity is weaker. The increases in nitrogen content can increase the inhibitor intensity and hinder abnormal growth of a mount of {110}⟨116⟩{110}⟨116⟩ grains and therefore enhance the sharpness of Goss texture.

High-silicon steel (6-6.5% Si) is believed to be applicable to magnetic devices operating at high frequencies because of its high permeability, low magnetocrystalline anisotropy, near-zero magnetostriction, low core loss, and low device noise [1]. However, the appearance of ordered phases, including B2 and D03, which are formed on the basis of the fundamental bcc crystal lattice [2], results in embrittlement and raises the level of difficulty of material deformation by conventional rolling. In recent years, high-silicon steel sheets with superior magnetic properties have been successfully fabricated through hot rolling combined with warm and cold rolling, as well as appropriate intermediate heat treatment [1, 3, 4, 5]. So far the studies about high-silicon steel have been mainly focused on the non-oriented high-silicon steel [1, 6, 7, 8], and there are few reports about producing grain-oriented 6.5 wt% silicon steel by rolling process. Grain-oriented 6.5 wt% silicon steels can be potentially applied in high-frequency transformer cores, which require lower core loss and higher magnetic induction along one direction. Increasing the silicon content can delay or hinder the development of the secondary recrystallization, and the normal growth of primary recrystallized grains requires much stronger inhibitors to be inhibited, which increases the difficulty of the preparation of grain-oriented 6.5 wt% silicon steel. Grain-oriented 6.5 wt% silicon steel also lacks some relevant theoretical studies. It is first prepared by the secondary recrystallization, and its magnetic properties are studied [9], but the characteristics of the secondary recrystallization behaviors are not clear. In recent years, some scholars use commercial electrical steel to prepare the grain-oriented high-silicon steel by annealing at high temperatures under a high vacuum and magnetic annealing [10], and others use silicon diffusion by SiO2 textile to prepare it and study the influences of low temperature heat treatment, cooling rate, and ordered phase on the iron loss [1, 11, 12, 13]. However, these researches do not involve the secondary recrystallization of 6.5 wt% silicon steels.

In this study, grain-oriented 6.5 wt% silicon steel sheets were produced by rolling processes. To reduce the slab reheating temperature and avoid the effect of warm rolling on the precipitation of the inhibitors, an acquired inhibitor method was used to form nitride as main inhibitor by nitriding [14, 15]. It was different to the conventional process of grain-oriented silicon steel, where the combination of warm rolling and cold rolling instead of one-stage cold rolling with a large reduction could reduce cracking in high-silicon steel. Oil quenching instead of water quenching could reduce the formation of brittle ordered phases and prevent the cracking in high-silicon steel sheets after normalizing. To clarify the characteristics of the secondary recrystallization behaviors of grain-oriented 6.5 wt% silicon steel sheets, the changes of microstructure and texture and the inhibitor precipitation during the secondary recrystallization annealing were studied by interrupt methods. Moreover, the effect of nitriding time on secondary recrystallization behaviors and magnetic properties of grain-oriented 6.5 wt% silicon steel was also investigated.

The high-silicon steel ingot used in this study was prepared by melting pure iron and silicon in an induction vacuum furnace. The main chemical compositions were C: 0.01, Si: 6.5, Mn: 0.16, S: 0.005, Al: 0.013, and N: 0.003 (in mass%). The ingot was forged into a 20-mm-thick plate at the temperatures ranging from 1050 to 900 ° C, hot-rolled to 2 mm thickness at the temperatures ranging from 1150 to 800 ° C, annealed at 950 ° C for 2 min and quenched in oil, and then warm-rolled to 0.67 mm at 650 ° C. Afterward, the warm-rolled bands were annealed at 800 ° C for 2 min, quenched in oil, and then cold-rolled to 0.23-0.3 mm at 350 ° C. After decarburization annealing at 850 ° C for 4 min, the oxide film was thinned by mechanical polishing. Then, the annealed sheets were variously nitrided under an 11% NH3, 67% H2, and 22% N2 mixed atmosphere at 750 ° C for 30, 60, and 90 s. The annealing separator, mainly consisting of MgO, was coated on the specimen surfaces. The secondary recrystallization annealing was performed under a 70% N2 and 30% H2 atmosphere with a heating rate of 15 ° C/h up to 1200 ° C and maintained at 1200 ° C for 5 h under a 100% H2 atmosphere for purification. Some of the annealed samples were extracted at every 25 ° C from 850 to 1100 ° C for texture and microstructure analysis.

The texture of samples was measured and analyzed by an Oxford Instruments HKL-Channel 5 electron backscattered diffraction (EBSD) system equipped using a Zeiss ULTRA55 scanning electron microscope. Types of the precipitates were observed by scanning electron microscopy (SEM), and the elemental composition was analyzed by energy-dispersive spectroscopy (EDS). The magnetic flux densities at 800 (B8) and 5000 (B50) A/m and the core losses P10/50 (P10/50 is determined at a magnetic flux density of 1.0 T and 50 Hz; the rest of the P values can be deduced by analogy) and P15/50 were measured by an electrical steel tester (NIM-2000E). The typical core losses ranging from 50 Hz to 20 kHz, including P10/50, P15/50, P10/400, P10/1k, P5/2k, P2/5k, P1/10k, and P0.5/20k, were measured by an electrical steel tester (MPG 200D).

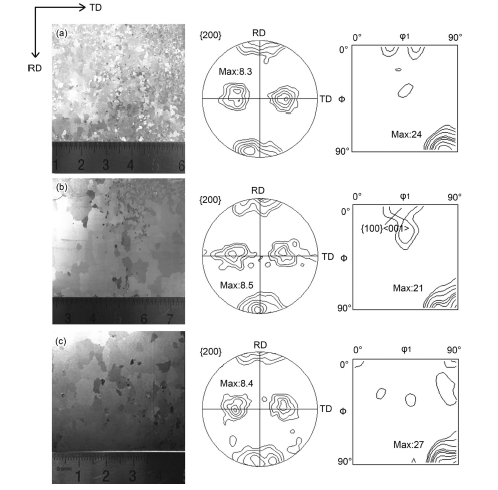

The macrostructures and {200} pole figures and the constant φ 2 = 45° sections of the orientation distribution functions (ODFs) of 0.3-mm-thick grain-oriented 6.5 wt% silicon steel sheets after secondary recrystallization annealing are shown in Fig. 1.

It can be seen that the percentage of secondary recrystallized grains increases with increasing nitriding time. The sample nitrided for 30 s shows a poor secondary recrystallization, and the grain size is not larger than 3 mm. The main texture component is {110}⟨116⟩{110}⟨116⟩ (φ 1 = 77° , Φ = 90° , φ 2 = 45° ), which is deviated 13° from Goss orientation, and a few of grain is 10° rotated-cube-oriented. The secondary recrystallization in the sample nitrided for 60 s develops better, and the orientations of secondary recrystallized grains are Goss and{110}⟨116⟩{110}⟨116⟩. Some of the secondary recrystallized grains are larger, but there still exist some fine grains, which are cube- and near-cube-oriented as shown in the ODF of Fig. 1b. The secondary recrystallization in the sample nitrided for 90 s is more complete than the former, and the sharpness of Goss texture increases. The average grain size exceeds 5 mm, and an individual grain size is up to 1 cm. Statistically, the area fractions of secondary recrystallized grains in these three samples are 23%, 82% and 95%, respectively.

The magnetic properties of grain-oriented 6.5 wt% silicon steel sheets at 50 Hz are listed in Table 1. It can be seen that the magnetic flux densities increase as nitriding time increases, and the values of B8 are 1.525-1.570 T, which are higher than that of high-silicon steel in previous literature [4, 5, 6, 7, 8, 9, 10]. The values of B50 are almost close to the saturation magnetic flux density Bs of 6.5%Si-Fe, which is 1.80 T.

| Table 1 Magnetic properties of grain-oriented 6.5 wt% silicon steel sheets at 50 Hz |

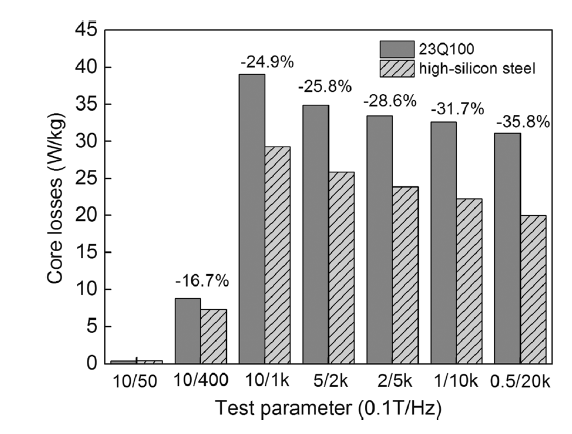

Comparison of core losses between grain-oriented 6.5% silicon steel and grain-oriented 3% silicon steel (23Q100, a grain-oriented steel grade in the specification of product manual means that the thickness is 0.23 mm and the core loss P1.7/50 is not greater than 1.0 W/kg) is shown in Fig. 2, and the thickness is all 0.23 mm. The core losses of grain-oriented 6.5% silicon steel at the frequencies ranging from 400 Hz to 20 kHz are much lower than that of grain-oriented 3% silicon steel by 16.7%-35.8%. This is because the percentage of hysteresis loss decreases, and the classical eddy current loss increases to become the main component of the total loss with increasing frequency. The resistivity of 6.5 wt% Si steel is nearly twice as high as that of 3% Si steel, so the grain-oriented 6.5% silicon steel sheets have lower core losses at high frequencies.

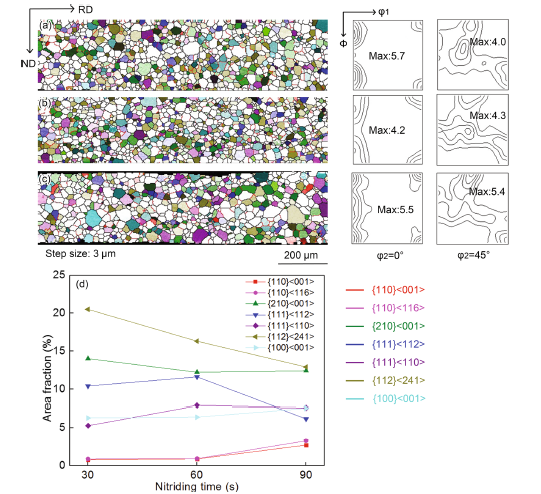

It is well known that the primary recrystallized textures have important influence on the growth behavior during secondary recrystallization. EBSD patterns are captured and analyzed to obtain information of the crystal orientation. The orientation images and ODFs (φ 2 = 0° , 45° ) of 0.3-mm-thick samples, which are nitrided for 30, 60, and 90 s after decarburization annealing, are shown in Fig. 3. The results of EBSD analysis show that the average grain sizes of these samples are 20-24 μ m, and the recrystallization textures mainly include γ -fiber (⟨111⟩⟨111⟩//ND) textures, cube textures, and strong η -fiber (⟨001⟩⟨001⟩//RD) textures with a peak at {210}⟨001⟩-{310}⟨001⟩{210}⟨001⟩-{310}⟨001⟩. Compared to the conventional grain-oriented silicon steel (CGO), {111}⟨112⟩{111}⟨112⟩ texture component in γ -fiber texture is weaker because of using special rolling method for high-silicon steel, which is the combination of warm rolling and cold rolling. As the nitriding time increases, the grain size increases, and the volume fractions of Goss, {110}⟨116⟩{110}⟨116⟩, and cube texture component increase (Fig. 3d). By contrast, the texture components of {111}⟨112⟩{111}⟨112⟩ and {112}⟨241⟩{112}⟨241⟩ decrease.

| Fig. 3 Orientation images and ODFs (φ 2 = 0° , 45° ; levels: 1, 2, 3, 4, 5) of the samples, which are nitrided for 30 sa, 60 s b, and 90 s c and their area fractions of main texture components d |

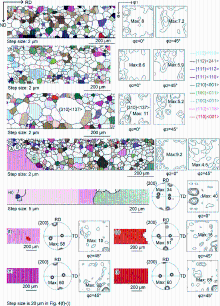

Figure 4 shows local orientation images, {200} pole figures, and ODFs of the samples, which are nitrided for 60 s and extracted at different temperatures during the secondary recrystallization annealing. The area fractions of main texture components in Fig. 4 are listed in Table 2. It is found that the abnormal growth of grain occurs at 875-900 ° C and their orientations are not Goss, such as the grain of {310}⟨137⟩{310}⟨137⟩ as shown in Fig. 4c, and the grain size reaches 200 μ m. However, a few of Goss grains begin abnormal growth at that time.

| Table 2 Area fractions of main texture components in Fig. 4 (%) |

The orientation of secondary recrystallized grain at 925 ° C is {110}⟨116⟩{110}⟨116⟩, as shown in Fig. 4d. The misorientation between the {110}⟨116⟩{110}⟨116⟩ grain and surrounding small grains (except A and B) ranges from 29° to 45° , which indicates the {110}⟨116⟩{110}⟨116⟩ grain having many HE boundaries, and the misorientation between the {110}⟨116⟩{110}⟨116⟩ grain and C grain is 34° , but the grain boundary migration has lagged because of the larger size of C grain. In addition, the grains in the central layer are larger than those in the subsurface layer during the heating process, which may be related to the difference in inhibitor intensity along the thickness direction, so it is necessary to study the condition of inhibitor precipitation. The size of secondary recrystallized grain is more than 1 mm at 950 ° C, as shown in Fig. 4e, and the orientations are approximate to {110}⟨116⟩{110}⟨116⟩ and {210}⟨001⟩{210}⟨001⟩ , but there are a few of residual island grains surrounded by 50° boundaries. In the samples extracted at higher temperatures, the size of secondary recrystallized grain is larger, and EBSD analyses of some regions indicate that the orientation is either Goss or {110}⟨116⟩{110}⟨116⟩ as shown in Fig. 4f-i.

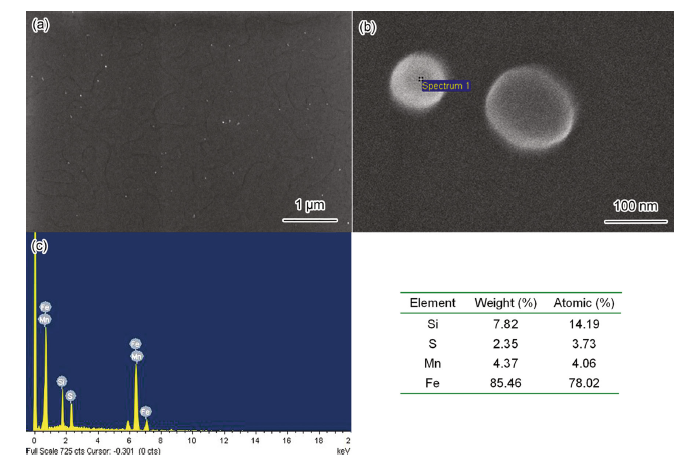

The precipitation driving force of initial inhibitors has been basically exhausted because of the use of a low slab reheating temperature before hot rolling and a series of warm rolling, cold rolling, and annealing, and the main inhibitors playing an important role in second recrystallization are obtained by nitriding after decarburization annealing. When NH3 comes into contact with the heated steel sheet, it disassociates into N and H. The active N atoms then diffuse into the steel sheet creating a nitride layer, and N will combine with Al to form AlN inhibitors at higher temperatures. Previous studies propose that there is an optimum volume fraction of the precipitates for the development of complete secondary recrystallization in 3% silicon steel, and the optimum nitrogen content after nitriding is between 0.013% and 0.024% [14, 15]. In this experiment, the nitrogen contents after nitriding for 30, 60, and 90 s are about 100, 160, and 230 ppm, respectively. The precipitates after nitriding for 60 s are observed by SEM and analyzed by EDS (Fig. 5), and the results show that the precipitate density is low whether in the surface or in the central layer, which is related to a small quantity of initial inhibitors and a low content of Al. EDS analysis indicates that the main type of the precipitates after nitriding for 60 s is MnS, and these particles are free of Al.

| Fig. 5 Distribution a, micrograph b, and EDS analysis c of the precipitates after nitriding for 60 s |

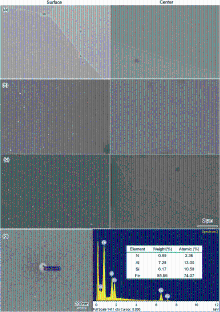

Distribution of the precipitates at 875, 900, and 925 ° C in the surface and the central layer of the samples nitrided for 60 s and EDS analysis of the precipitates are shown in Fig. 6. It is found that most dispersed precipitates are AlN and (Al, Si)N. The size and quantity of precipitates increase as the temperature increases, and the particles coarsen at 900 ° C. At the same temperature, the nitride particles distributed on the surface are still more than those in the central layer, which indicates that the inhibitor strength against grain growth in the surface are stronger than that in the central layer. The mechanism of the inhibitor precipitation with the nitride is related to the diffusion of solute atoms N in the ferrite. As the diffusion carries on, the constituent fluctuation occurs before the precipitation of particles, and structural changes happen when the element concentration increases to the composition of second phases. The increase in temperature promotes the atom diffusion and particle nucleation relying on the thermal activation.

| Fig. 6 Distribution of the precipitates at 875 ° C a, 900 ° C b, and 925 ° C c in the surface and the central layer of samples nitrided 60 s and EDS analysis of the precipitates d |

Figure 6 shows that the inhibitor density is relatively low, and the possible reason is as follows. On one hand, there is a small amount of inherent inhibitors in the steel and a low initial content of Al against forming a large number of AlN inhibitors; on the other hand, compared to the 3% silicon steel, more compact SiO2 layers formed on the surface of high-silicon steel are barriers for N to diffuse into steel interior. Therefore, the inhibitor quantity on the whole is small.

The primary recrystallized texture of grain-oriented 6.5 wt% silicon steel is different from that of grain-oriented 3% silicon steels. The main primary textures of grain-oriented 3% silicon steel using nitriding to acquire inhibitors are {114}⟨418⟩{114}⟨418⟩ and γ -fiber textures [16]. CGO steel reveals a cube texture and a strong γ -fiber texture [17]. By contrast, high-permeability (Hi-B) electrical steel shows a 25° rotated cube texture and a strongest texture of {111}⟨112⟩{111}⟨112⟩ [18]. Because more Σ 9 coincident-site-lattice (CSL) boundaries between {111}⟨112⟩{111}⟨112⟩ and Goss grains have a high mobility, which favor the abnormal growth of Goss grains [19]. Therefore, a much stronger {111}⟨112⟩{111}⟨112⟩ texture in primary recrystallization is desirable. However, the high-silicon steel cannot be cold-rolled with a large reduction because of embrittlement, and the combination of warm rolling and cold rolling with a medium reduction causes that the {111}⟨112⟩{111}⟨112⟩ texture is not strong enough. In the primary recrystallized microstructure of high-silicon steel sheets (Fig. 3), the accurate Goss grains are mainly distributed on the surface and the subsurface layer, while {110}⟨116⟩{110}⟨116⟩ grains are mainly distributed in the subsurface and the central layer. A previous study indicates that {110}⟨116⟩{110}⟨116⟩ grains have 72% of the frequency of HE boundary in primary recrystallized microstructure; namely that the area fraction of the grains having near {110}⟨116⟩{110}⟨116⟩ orientation is only 2% in primary recrystallized microstructure. However, after secondary recrystallization, the area fraction is 63% [20]. Since the inhibitor quantity on the surface is higher than that in the central layer of high-silicon steel sheets, the abnormal growth of more {110}⟨116⟩{110}⟨116⟩ grains in the subsurface and the central layer having a lot of 20-45° high-energy (HE) boundaries easily occur when the inhibitor quantity is not enough and the inhibitor intensity is weaker, and the size of secondary recrystallized grains is small as shown in the macrostructure of the sample nitrided for 30 s. As the nitrogen content increases after nitriding, the inhibitor quantity increases and the pinning enhances. Without the competition of a mount of {110}⟨116⟩{110}⟨116⟩ grains, the secondary recrystallization of Goss grains develops better and the size of secondary recrystallized grain is larger. In addition, the sharpness of Goss texture increases, as shown in the macrostructure of the sample nitrided for 60 and 90 s.

By rolling and nitriding processes, 0.23- to 0.3-mm-thick grain-oriented 6.5 wt% silicon steel sheets are produced. The core losses of grain-oriented 6.5 wt% silicon steel at frequencies ranging from 400 Hz to 20 kHz are lower than that of grain-oriented 3 wt% silicon steel with the same thickness by 16.6%-35.8%. The secondary recrystallization in high-silicon steel sheets develops more completely as the nitrogen content increases after nitriding, secondary recrystallized grain sizes become larger, and the sharpness of Goss ({110}⟨001⟩{110}⟨001⟩) texture increases. Because more {110}⟨116⟩{110}⟨116⟩ grains in the subsurface and the central layer of the sheets have a lot of 20° -45° HE boundaries in addition to Goss grains, {110}⟨116⟩{110}⟨116⟩ can be a main component through selective growth during secondary recrystallization when the inhibitor quantity is not enough and the inhibitor intensity is weaker. The increase in nitrogen content can increase the inhibitor intensity and hinder abnormal growth of a mount of {110}⟨116⟩{110}⟨116⟩ grains and therefore enhance the sharpness of Goss texture.

Financial support from the National High-Technology Research and Development Program of China (No. 2012AA03A505) is gratefully acknowledged.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|