Microstructural evolution in nonequilibrium solidification of Ti-48Al-xNb alloys with Nb contents ranging from 2 to 8 at% has been studied by containerless electromagnetic levitation. Levitated drops of controlled undercooling were quenched onto chill copper substrates and subjected to phase and microstructure analysis. With increasing Nb content, the solidification path changes gradually from hyperperitectic solidification to hypoperitectic solidification and both solidification segregation (S-segregation) and β-solidification gradually increase. A transition from typical hypoperitectic solidification to a sole solidification of the β phase beyond a critical undercooling is revealed for the Ti-48Al-8Nb hypoperitectic alloy. For the Ti-48Al-2Nb alloy, the morphologies of the primary β dendrites are not observed. With increasing undercooling, the coarsening of the lamellar colonies occurs, which can be attributed to the transition of the primary β dendritic morphology. Furthermore, the solute concentration profiles for the final solidification microstructure are obtained to examine the segregation behaviors of alloying elements. With increasing Nb content, the undercooling eliminating S-segregation gradually increases.

After several decades of research and development of titanium aluminides, the TiAl-based alloys are considered as the most promising candidates for aero-engine and automotive components [1, 2, 3]. However, the practical use of TiAl alloys still needs the improvement in properties, such as room temperature ductility, high temperature strength and oxidation resistance[4]. Alloying element Nb is added to improve the high oxidation resistance, high temperature strength and lamellar structure stability. However, more Nb additions change the TiAl phase diagram greatly and lead to the transition of the dendrite morphology [5]. The occurrence of peritectic reaction and subsequent solid-state transformation result in a complex multiphase material, which may cause significant microstructural inhomogeneity and induce a series of undesirable mechanical properties [6]. At present, the TiAl alloys can be classified into three categories: conventional alloys; high Nb-containing alloys; and β -solidifying alloys. The Nb content of conventional TiAl alloys is below 5 at%. However, the Nb content of high Nb-containing alloys ranges from 5 to 10 at% and the Nb content of β -solidifying alloys ranges from 2 to 8 at%[7]. Comparing with the microstructure of cast Ti-48Al-2Cr-2Nb alloy, we found that the dendritic size is obviously larger and the segregation becomes more serious for high Nb-TiAl alloy. Imayev et al. [8] reported that severe microstructure inhomogeneity could result in poor properties of TiAl alloys. Furthermore, high Nb addition also leads to the increasing cracking tendency and poor casting properties of cast alloy. Thus, it is of great importance to investigate the effect of Nb content on solidification pathways, microstructural evolution and microsegregation in cast Ti-Al-Nb alloys.

Microstructural control is also important for achievement of optimum properties. Many studies on solidification behavior of TiAl alloy have been carried out, and complex microstructures have been obtained. Liu et al. [9] showed that the variation of the growth rate within the range of 2-5 µ m/s results in cellular-dendritic transition in directionally solidified Ti-46Al-8Nb (at%) alloy. While Ding et al. [10] reported that the solidification path changes from the L → L+β → L+β + α → α to the L → L+β → α + γ with the increase in the growth rate for Ti-45Al-8Nb alloy during directional solidification. It is recognized that undercooling has an important effect on the solidification sequence and can cause different microstructural characteristics in TiAl alloys. The phase formation processes from undercooled melts of TiAl alloys also have been a subject of various investigations. The phase selection principles and metastable phase formation at high solidification speed and moderate cooling rates were established by using undercooled levitated alloys [11, 12, 13, 14]. However, there is still no detailed investigation about effect of Nb content on microstructural evolution of peritectic Ti-48Al-xNb alloys by undercooled solidification because it has a great effect on the hot cracking behavior and embrittlement at elevated temperature.

Since liquid γ -TiAl-based alloys are highly reactive with the majority of crucible materials, the electromagnetic levitation containerless technique is very suitable for the investigation of rapid solidification [15]. It can obtain different undercoolings to investigate the transition of solidification path and to estimate the ease or complexity of controlling microsegregation. The aim of the present work is to study microstructural evolution and microsegregation of Ti-48Al based alloys with Nb contents ranging from 2 to 8 at% in undercooling solidification and provide theoretical basis for new alloy design of TiAl-based alloys.

Ternary master alloys with a nominal composition of Ti-48Al-(x = 2, 4, 6, 8) Nb (mol%) were prepared by arc-melting under a Ti-gettered argon atmosphere. The alloys were re-melted for five times in order to ensure the compositional homogenization. The as-casted ingot was cut into segments weighing about 1.2 g for undercooled experiments.

The near equilibrium experiments were performed by vacuum induction melting (VIM) equipment technique. The Ti-48Al-(x = 2, 4, 6, 8) Nb samples of 18 mm in diameter and 20 mm in length were wire-cut from the as-casted ingot and then the samples were induction melted and cooled in ceramic crucibles coated with Y2O3. Before melting, the vacuum chamber was evacuated to 10-3 Pa and backfilled with pure argon up to 0.08 MPa, and this process was repeated three times to reduce the oxygen content. The sample was overheated to about 100 K above its liquidus. After keeping for about 1 min, the melt was cooled to about 100 K below its liquidus at the cooling rate of 10 K/min and then followed by air cooling to room temperature.

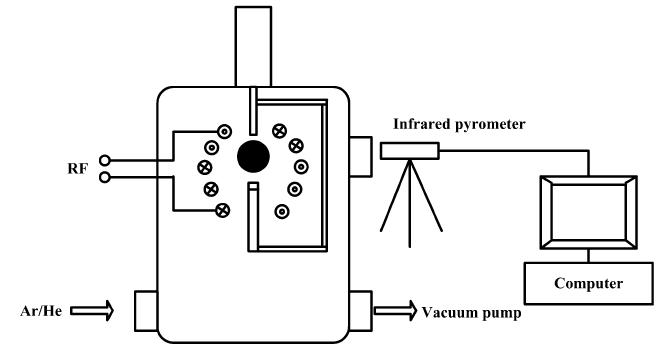

The undercooling experiments were performed in an electromagnetic levitation facility, as shown in Fig. 1. First, the vacuum chamber of the electromagnetic levitation facility was evacuated to 10-4 Pa and then filled with high-purity Ar gas. The sample was melted by induction heating and further overheated to about 100 K above its liquidus. After keeping for about 1 min, the sample was cooled by a gas stream of He. In the undercooling experiments, the sample was superheated and cooled by purified He gas stream across their surface. Solidification was induced at various undercooling levels by triggering the drop and the sample was quenched onto the substrate by cutting off the power. The temperature-time curves during melting and cooling process were recorded by a two-color pyrometer with a precision of 5 K and a response time of 10 ms.

Specimens after levitation were approximately ellipsoidal due to the effects of gravity and the electromagnetic field, with a diameter of approximately 5 mm. For metallographic analysis, each sample was sectioned along its long axis and then mounted so as to observe their cross section. The as-solidified samples were polished and etched with Kroll’ s reagent to investigate the microstructure. The phases and the microstructures were revealed by X-ray diffraction (XRD), optical microscopy, and scanning electron microscopy (SEM). The different phases were discriminated on the basis of their gray-level contrast on high-resolution back-scattered electron (BSE) images. Phase and composition were identified by a D/max-2400 X-ray diffractometer and an INCA energy-dispersive X-ray spectrometer.

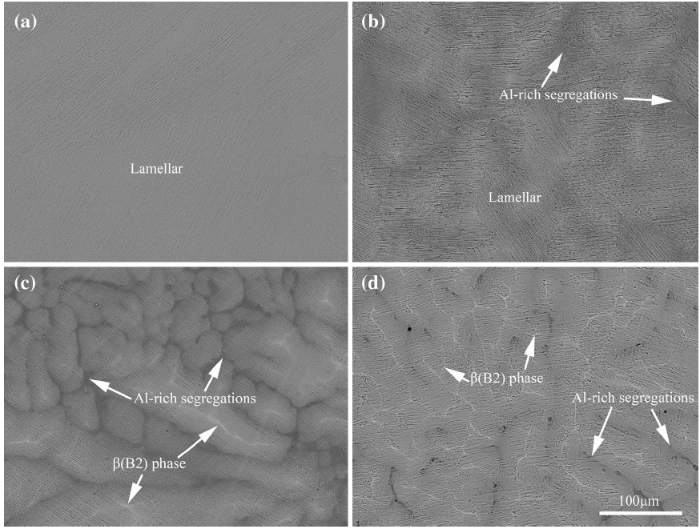

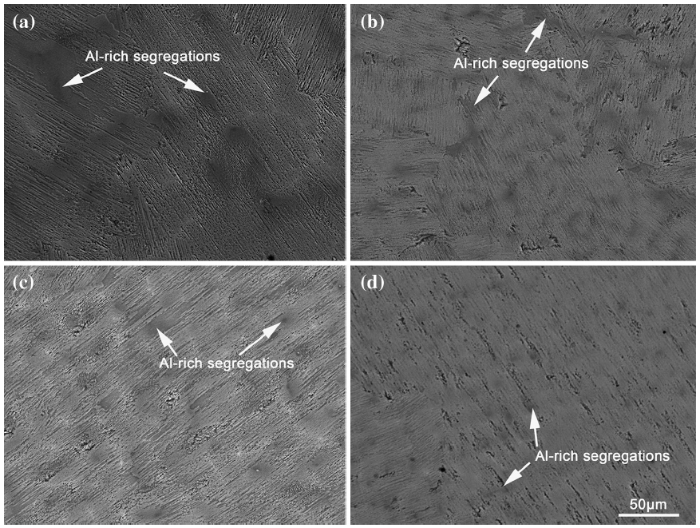

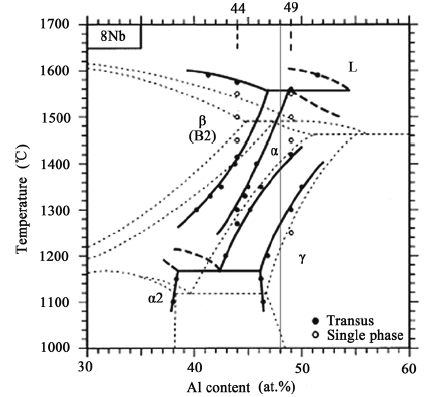

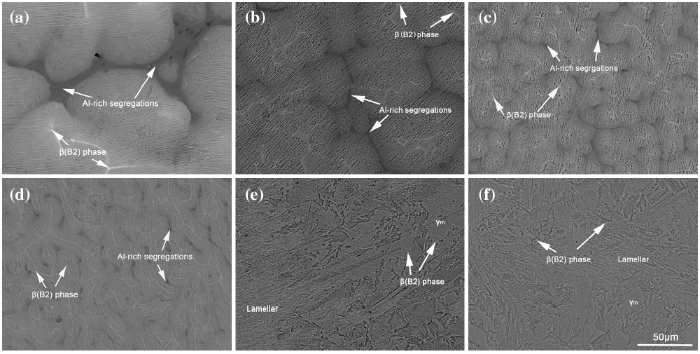

High Nb addition changes the TiAl phase diagram greatly, leading to the solidification behavior different from binary TiAl alloys, as shown in Fig. 2[12]. The 8Nb-TiAl phase diagram is indicated by a solid line, while the TiAl binary phase diagram is shown by a dashed line. In order to determine the transition point from hyperperitectic solidification to hypoperitectic solidification for Ti-48Al-xNb alloys, the microstructures in near equilibrium solidification were observed by BSE. The typical solidification microstructures under near equilibrium conditions for the Ti-48Al-xNb alloys are shown in Fig. 3. The dendrite morphologies cannot be observed in the Ti-48Al-2Nb alloy, indicating that the solidification mode is the hypoperitectic solidification as shown in Fig. 3a. With increasing Nb content, the dendrite morphologies were found indistinctly. The microstructure indicates that the interdendritic liquid is frozen by progressively thickening the α envelopes, as shown in Fig. 3b. For the Ti-48Al-(6-8) Nb alloys, white contrast segregation veins, rich in Nb and poor in Al, are residual traces from the solid-state transformation β /α , locally giving rise to formation of B2-particles, as indicated by Chen et al. [12]. However, the interdendritic region appears dark in the BSE contrast. The solidification mode is transformed into the hypoperitectic solidification. The Ti-48Al-xNb alloys with 2 ≤ Nb < 4 at% solidify according to the pathway L → L+β → L+β + α → L + α → α → …. The solidification pathway changes to L → L+β → L+β + α → β + α → … for the Ti-48Al-(6-8) Nb alloys. Therefore, with Nb varying from 2 to 8 at%, the solidification path changes gradually from hyperperitectic solidification to hypoperitectic solidification and the transition point of solidification path occurs at the Nb content of about 4 at%. The evolution of solidification microstructure under non-equilibrium conditions shows some different morphologies as undercooling increases. Taking Ti-48Al-8Nb hypoperitectic alloy and Ti-48Al-2Nb hyperperitectic alloy as examples, the analysis will be described in the following section.

| Fig. 2 Section of the phase diagram of TiAl-8Nb[12] |

3.2.1 Characterization of Bulk Undercooled Ti-48Al-8Nb Alloy

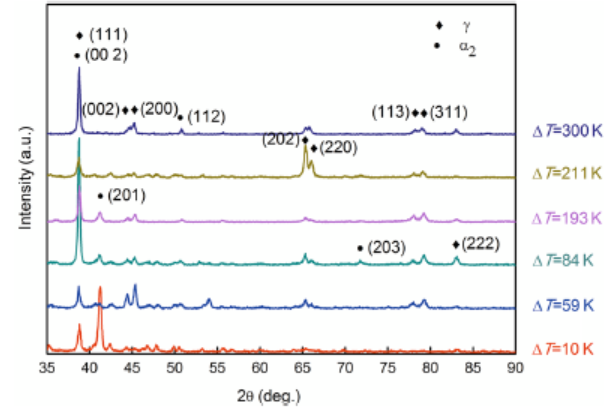

XRD patterns taken from samples solidified at different undercoolings (Δ T) are plotted in Fig. 4. Samples corresponding to low undercoolings exhibit two-phase mixture, namely γ and α 2, respectively. However, samples solidified at undercoolings above 211 K contain predominantly γ phase. The content of B2 phase is negligible within the detectable limit of XRD.

3.2.2 Microstructural Evolution in Nonequilibrium Solidification of Ti-48Al-8Nb Hypoperitectic Alloy

In order to investigate the transition of solidification path and evaluate the difficult degree of controlling segregation, all kinds of different undercoolings were obtained for the Ti-48Al-8Nb alloy. The maximum undercooling of 300 K for Ti-48Al-8Nb alloy can be achieved. Figure 5 shows the microstructures of the as-solidified Ti-48Al-8Nb alloy in nonequilibrium solidification. At undercooling Δ T = 10 K, the β phase primarily precipitates. After that, the peritectic reaction of α phase occurs at dendrite edges of primary β phase. As the reaction proceeds, α phase would separate β phase from the liquid phase gradually. The peritectic α phase envelopes the primary β phase firstly by nucleation and then the dissolution of primary β and growth of peritectic α happen near the triple-junctions. Once the peritectic reaction is complete, the peritectic α phase can be thickened by the direct precipitation from the liquid and from the β phase during the peritectic transformation. Then, the α → γ transformation is seen in an interdendritic region. EDS analysis exhibited that Al content rises to about 53.5 at%. The residual β in peritectic transformation will also result in subsequent β → α solid-state transformation. Further cooling leads to a diffusion-controlled precipitation of γ -TiAl from α -phase according to the Blackburn orientation relationship [16]. The formation of lamellar colonies has a negligible influence on the as-solidified morphologies, as shown in Fig. 5a. At a medium undercooling of 59 K ≤ Δ T ≤ 193 K, the coarse dendrites transform into fine dendrites, as shown in Fig. 5b. When the undercooling is less than Δ T = 193 K, the primary dendrites are contrasted with severe segregation of Al in the interdendritic regions. The Ti-48Al-8Nb alloy forms a coarse dendrite microstructure, consisting of lamellar α 2 + γ and interdendritic γ -phase. The Nb accumulation in the center of the dendrites is a typical sign of a β → α solid-state transformation, which is often used as a criterion for the β primary solidification mode[17]. As the undercooling Δ T ≤ 193 K, the solidification path can be described as L → L+β → L+β + α → β + α . Once the undercooling exceeds approximately 193 K (Fig. 5d), the Widmanstä tten structure can be observed, where peritectic reaction cannot proceed and γ lamellar precipitation within α plates is suppressed. Peritectic solidification characteristics can be confirmed from Al-rich segregations resulted from the peritectic solidification reaction [18]. A sole solidification of β phase is formed, and α plates with orientations according to the Burgers relationship are precipitated from the β phase. The final microstructure is developed during the subsequent solid-state transformations. Subsequently, γ phase formed by the α → γ m massive transformation, and the microstructure is characterized by Widmanstä tten structure similar to near α or (α + β ) Ti alloys as shown in Fig. 5e, f. The intensity of the γ phase peaks increases at Δ T = 300 K, indicating the massive γ phase occurs. It gives evidence that γ m grains are formed at Δ T = 300 K. It is known from the phase diagram that Nb addition to binary Ti-Al changes the reaction pathway from α → α 2+ γ toward α → γ . The α + γ two-phase field shrinks substantially and the γ transformation line raises with increasing Nb content [19]. The solidification path can be described as L → L+β → β → β + α . Therefore, a remarkable morphological transition from typical hypoperitectic solidification to a sole solidification of the β phase resulting in the suppression of the peritectic reaction occurs with increasing undercooling, which is also consistent with previous work on the undercooled Fe-Ni alloy reported by Chen et al. [20].

| Fig. 5 BSE images of the Ti-48Al-8Nb alloy at different undercoolings: a Δ T = 10 K, b Δ T = 59 K, c Δ T = 84 K, d Δ T = 193 K, e Δ T = 211 K, f Δ T = 300 K |

3.2.3 Characterization of Bulk Undercooled Ti-48Al-2Nb Alloy

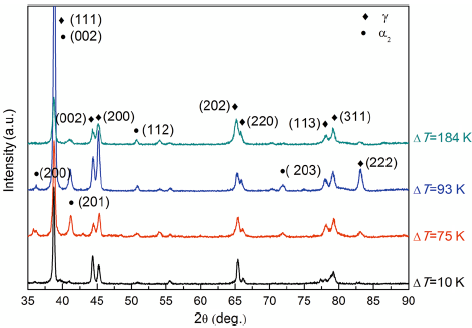

XRD spectra taken from the samples solidified at different undercoolings are shown in Fig. 6. Samples at different undercoolings have two phases, namely γ -TiAl phase and α 2-Ti3Al phase in the alloy, which is consistent with the corresponding BSE observation. The diffraction intensity of the γ (111)/α 2(002) peaks dramatically increases in the sample solidified at a undercooling of 93 K. It can be also found that the relative content of α 2 and γ phase does not significantly change the microstructures. Thus, the strongest diffraction peak on the XRD spectra is ascribed to preferred orientation growth of dendrite. That partly explains the directional fine dendrites formed at Δ T = 93 K. Meanwhile, the diffraction peaks of phases at Δ T = 93 K shift to higher angles which suggests that interplanar spacing decreases due to the distortion of the crystal lattice. However, compared with Ti-48Al-2Nb alloy at Δ T = 93 K, it is found that the diffraction peaks of phases in rapidly solidified Ti-48Al-2Nb alloy at Δ T = 184 K rate shift to lower angles, which means that interplanar spacing increases due to the distortion of the crystal lattice. The change of undercooling is found to change their relative fractions only.

3.2.4 Microstructural Evolution in Nonequilibrium Solidification of Ti-48Al-2Nb Hyperperitectic Alloy

The maximum undercooling achieved in the present work is 184 K, and the typical solidification microstructures at different undercoolings are shown in Fig. 7. If the undercooling is small (Δ T = 10 K), the primary phase β nucleates initially and coarse β dendrites are formed. Once the following peritectic reaction begins, β and liquid phase react with each other and α phase forms. After solidification has completed, α phase will grow into the primary β phase. Following by a further decrease of temperature, the transformation of α → α 2 + γ occurs and the final lamellar microstructure is observed, as shown in Fig. 7a. When the undercooling is 75 K, the overall cross section is occupied by equiaxed dendrites and presented higher branches which are different from the aforementioned coarse dendrites, as shown in Fig. 7b. When the undercooling is 93 K, β dendrite morphology transition occurs from well-branched dendrites to developed directional fine dendrites/cellular, as shown in Fig. 7c. This phenomenon is observed for undercooled conventional alloy [21]. The strongest diffraction peak on the XRD spectra at Δ T = 93 K is ascribed to preferred orientation growth of dendrite, as shown in Fig. 6. That partly explains the directional fine dendrites formed at Δ T = 93 K. It is worth noting that the lamellar colonies size coarsening occurs. Such morphologies of coarsening lamellar colonies are commonly observed for directionally solidified ingots [22]. Previous study also showed that the α phase grew through β dendrites in such a way that coarse columnar grains arose [23]. This appears to be a consequence of the high nucleation rate and very rapid growth rates that accompany the high-temperature solidification reaction. With increasing undercooling, the S-segregation also gradually decreases. The EDS analysis also proves this. Figure 9 illustrates the Al contents in the interdendritic zone at different undercoolings for Ti-48Al-(2, 8) Nb alloys. As the undercooling Δ T = 184 K for Ti-48Al-2Nb alloy, the microsegregation can be hardly detected and the solute trapping effect becomes more significant. Compared with the microstructures in of the Ti-48Al-8Nb alloy (Fig. 4), solidification microsegregation in the interdendritic zone is relatively small, regardless of the undercooling is large or small. It is mainly because of the differences of the solidification path.

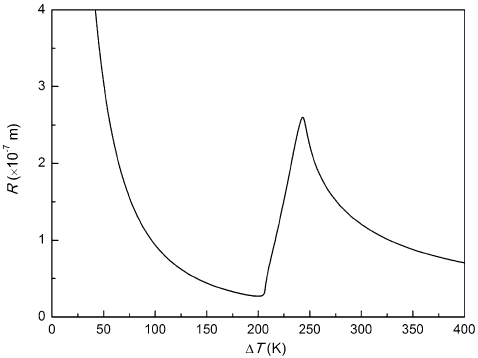

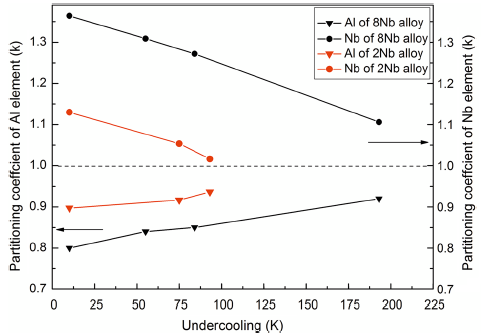

The above results reveal that the undercooling has significant effects on transformation pathway and microstructural evolution of nonequilibrium solidified Ti-48Al-xNb alloys, which can be associated with variation in the intensity of the microsegregation. With the increase of undercooling, the dendrite tip radius decreases and then the degree of segregation decreases gradually as shown in Fig. 8. Due to the difficulty of getting the physical parameters of Ti-48Al-2Nb alloy, the alloy composition of Ti-48Al-2Nb approximately corresponds to the binary Ti-48Al alloy by Al-equivalent calculation. 1 at% of Nb addition to Ti-Al binary alloy is known to shift the phase boundaries to the Al-rich side by 0.3% [24]. Figure 8 shows the relationship between calculated dendrite tip radius of the β dendrites versus the undercooling. With the increase of undercooling, the dendrite tip radius decreases for Δ T < 205 K. Therefore, it is necessary to determine the evolution of the microsegregation coming from both solidification and solid-state transformation processes with different undercoolings. In order to analyze the undercooling impacts on the microsegregation, EDS was applied to investigate the solute redistribution in the interdendritic liquid and dendrite core. The redistribution of solutes during solidification induces microsegregation ultimately. Solidification microsegregation is characterized by segregation coefficient. A segregation coefficient k is defined as the ratio of the average concentration of the element in the dendrite cores to that in the interdendritic regions, i.e., k = Cd/Cid [25]. The k < 1 indicates that the elements segregate to the interdendritic regions and this element is positive segregation element. While k > 1 indicates that the elements partition to the dendrite cores and this element is known as negative segregation element [26]. Figure 9 shows the relationship between the partition coefficients of Al and Nb element and undercooling. The interdendritic region was significantly enriched with Al, while Nb was almost distributed in dendrite cores. With the increase of undercooling, microsegregation decreases gradually for Ti-48Al-(2, 8) Nb alloys. With increasing Nb content, the undercooling eliminating S-segregation gradually increases. The transition of undercoolings for the Ti-48Al-2Nb and the Ti-48Al-8Nb alloys are about 93 and 193 K, respectively. Compared with the Ti-48Al-8Nb alloy, S-segregation can be more easily eliminated for the Ti-48Al-2Nb hyperperitectic alloy. Namely, eliminating S-segregation becomes increasingly difficult with increasing Nb content. For Ti-48Al based alloy, decreasing S-segregation can be obtained by controlling Nb content.

1.With increasing Nb content in Ti-48Al alloy, the solidification path changes gradually from hyperperitectic solidification to hypoperitectic solidification and both S-segregation and β -segregation gradually increase in near equilibrium solidification.

2.For the Ti-48Al-8Nb hypoperitectic alloy, a transition from typical hypoperitectic solidification to a sole solidification of the β phase beyond a critical undercooling of 193 K was revealed. For the Ti-48Al-2Nb hyperperitectic alloy, a morphological transition occurs beyond a critical undercooling of 93 K, which can be attributed to the dendritic-cellular growth of primary β phase.

3.With increasing Nb content, eliminating S-segregation becomes increasingly difficult. Decreasing S-segregation can be obtained by controlling Nb content for Ti-48Al based alloy.

Acknowledgments: This research was financially supported by the National Basic Research Program of China (“973” Project, Grant No. 2011CB605503) and the 111 Project of Northwestern Polytechnical University (Grant B08040).

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|