In this work, low-density electric current pulse (ECP) has been applied to submerged entry nozzle (SEN) and its effect on the morphology of the inclusion buildup and the distribution of the inclusions in slab has been explored. The results reveal that under the unique effects of ECP, part of small inclusions less than 10 μm is expelled through the boundary layer along the current direction to form dense inclusion buildup. This method is of great potential to prolong the service life of SEN and improve the quality of the steel product.

The development and application of submerged entry nozzle (SEN) for continuous casting are considered as an epochal progress to improve quality and productivity in steel industry [1]. However, in the course of the casting of aluminum killed steel, part of alumina inclusions in molten steel deposit on the inner wall of SEN to form porous inclusion buildup. With the increase in inclusions deposition, the casting procedure might be interrupted by the clogging of SEN, and the quality of the slabs always decreases for the falling off the deposited inclusions into molten steel [2, 3]. Hence, the control of inclusions deposition on the inner wall of SEN is of great importance for not only prolonging SEN life but also improving steel quality[4].

The deposition of alumina inclusions on the inner nozzle wall can be separated into three distinct stages: (1) the formation of inclusions, (2) transport of these inclusions to the nozzle wall, and (3) attachment of the inclusions on the inner wall of nozzle [5]. Up to now, some methods have been developed to decrease the effect of the former two stages [5, 6, 7, 8, 9, 10] and the following mechanisms have been proposed: (1) Temperature drop causes a decrease in the solubility of oxygen in the steel [6, 7]; (2) aluminum in the liquid steel is oxidized [8, 9]; (3) alumina inclusions transport in stagnation zones[10]; (4) suboxide gases or carbon monoxide react with aluminum in the melt on the nozzle-steel interface [11]. However, there are few reports concerning on attachment of the inclusions on the inner wall.

In this work, the effect of electric current pulse (ECP) on the attachment of inclusions on the inner wall was discussed.

In order to eliminate the effect of operational condition on the deposition of inclusions, such as the content of inclusions in molten steel, casting temperature, and casting speed, the experiment was carried out on an exactly symmetrical two-strand slab continuous caster with same operational parameters, and one strand was selected for ECP treatment and another one without ECP treatment for comparison. The detailed operational parameters were: casting temperature is (1560 ± 10) ° C, slab size is 1200 mm × 230 mm, casting speed is 1200 mm/min except for ladle changing period.

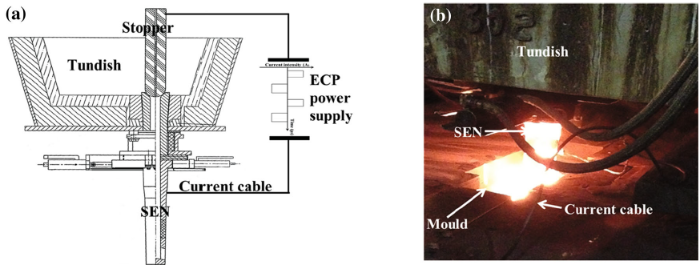

Figure 1a illustrates the schematic diagram of ECP treatment. SEN and stopper are connected to ECP power and flowing molten steel. Because of high content of graphite, the bodies of SEN and stopper have excellent conductivity even at high temperature, and the electric potential difference in ECP power is mainly exerted on the inclusion buildup in the inner wall of SEN. Moreover, as shown in Fig. 1b, the temperature of the connection joints on the SEN and stopper is close to 1500 ° C, and special treatments of oxidation protection, connecting, and insulation on the joints must be conducted.

Ahead of the casting process, two same SENs were equipped for a newly built tundish and preheated for 90 min. Then, the tundish with SENs was fast transferred to casting platform to carry out continuous casting operation. ECP treatment was started as soon as the liquid level of the mold kept at a relative steady state, and the average current density kept at 0.4 A and the frequency fixed at 20 kHz.

When the casting time reached to the setting time, the SENs were taken off from the tundish and cut into parts along axis for the determination of properties of the inclusion buildup. Therein, the bulk density was detected by automatic gravimeter and the true density was determined by multi-pycnometer. Simultaneously, the mass of inclusion buildup per unit length was measured by the high-accuracy balance, which was equipped on the automatic gravimeter. The thickness and roughness of the inclusion buildup were analyzed by laser rangefinder. The microstructure and composition of the inclusion buildup were observed by the field emission scanning electron microscopy (FE-SEM) equipped with an energy dispersive spectrometer (EDS).

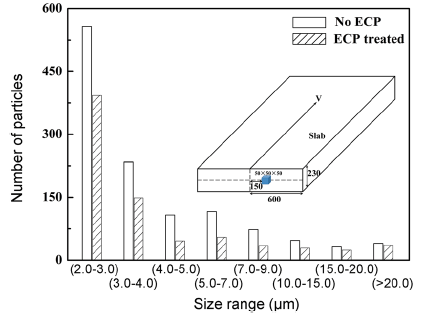

In every experiment, samples about 50 mm × 50 mm × 50 mm for inclusion distribution determination were almost simultaneously cut from the slabs produced in the two strands, and the details are schematic shown in Fig. 2. After elaborately cut and polished, the distribution of inclusions of the samples was automatically determined by ASPEX inclusion analyzer[12], and the scanning area is ~45 mm2; the analyzed size range of the inclusions is 1-227.8 μ m.

The application of ECP treatment did not bring about any trouble during casting process, and the fluctuation of liquid level in the mold was as low as ± 1 mm. Furthermore, the subsequent hot rolling revealed that all the slabs produced by ECP-treated strand reached the product requirements, and about 2.0% slabs produced by the comparison strand did not reached the requirements for surface defects.

Figure 2 shows the distribution of the inclusions in the slabs with and without ECP treatment. It could be found that the amount of the inclusions smaller than 10 μ m in the ECP-treated slab was less than that in the slab without ECP treatment, which implied that under the effect of ECP, lots of inclusions smaller than 10 μ m were transported to the inner wall of SEN during the molten steel flowing across the SEN. In addition, another ASPEX determination result revealed that the inclusions index of the ECP-treated slabs was 0.109%, and that of the comparison slabs was 0.128%. Because the others parameters of the producing process of the slabs are the same, the amount of depressed inclusions in the slab of ECP-treated strand might transport to the inner wall of the SEN.

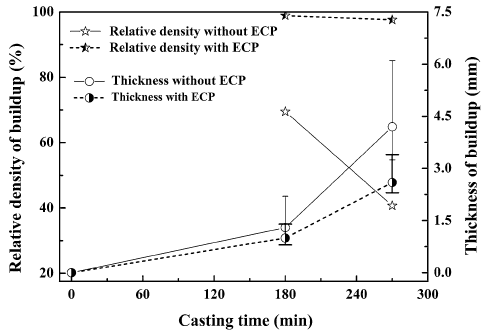

Figure 3 shows the average relative density and thickness of the inclusion buildups. It can be seen that in the sample with the ECP-treated SEN is almost full dense inclusion buildup, while that on the SEN without ECP treatment is very loose, and its relative density dramatically decreases from about 70 to 40% when the casting time is prolonged from 180 to 270 min. Hence, it can be deduced out that the application of ECP during continuous casting is beneficial to the densification of the inclusion buildup. In addition, it could be found that the thickness and roughness of the inclusion buildup, especially for the SEN without ECP treatment, sharply increase with the prolongation of casting time. Moreover, the weight of the inclusion buildup per unit length of the SEN without ECP treatment is less than that of the ECP-treated SEN. From the results of ASPEX determination, it can be deduced out that the application of ECP is favor to the transport of the inclusions to the inner wall of SEN.

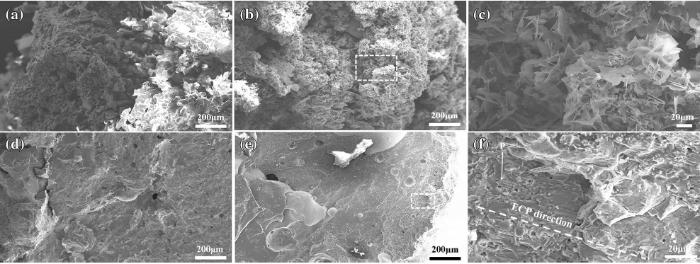

Figure 4 shows the microstructures of the inclusion buildups on the nozzles casted for 270 min, and it is very interesting to find that in the inclusion buildup of the SEN without ECP treatment, the inclusions closing to the interface of the inclusion buildup and molten steel are very loose and lamellar grains randomly contact each other. On the contrary, the inclusion buildup of the SEN treated with ECP is very dense and its grains parallel to the current direction. So, it can be deduced out that the ECP treatment is beneficial to the transport of the inclusions to the inner wall of the SEN and the subsequent densification of the inclusion buildup.

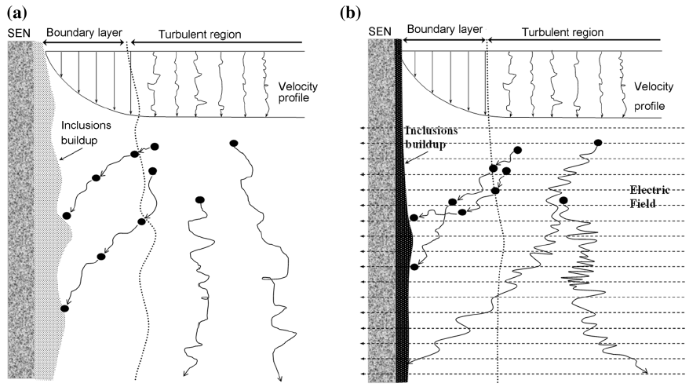

As to the transport of the inclusions to the inner wall of SEN, Fig. 5 reveals the movement of the inclusions closing to the inner wall of SEN. As shown in Fig. 5a, for the SEN without ECP treatment, a thin layer of molten steel, named boundary layer, exists along the wall of nozzle as a result of the viscosity of the molten steel. The flow velocity increases from zero at the wall to free steam velocity at some distance from the wall, and the thickness of the boundary layer (δ ) can be calculated as 27 μ m according to the following equation [5]:

$$\delta = \frac{5v}{{u_{* } }}, (1)$$

where v is the kinetic viscosity (8.8 × 10-7m2/s), \(u_{* }\) is the friction velocity (for SEN in the study, 0.162 m/s). Hence, the inclusions deposited on the inner wall of SEN must cross through the thin boundary layer. However, the transport of the inclusions endures a drag force and the travel distance named stopping distance (\(S_{\text{d}}\)), which is expressed [5]:

$$S_{\text{d}} = \frac{{u_{\text{p}} d_{\text{p}}^{2} (\rho_{\text{f}} - \rho_{\text{p}} )}}{18\mu } + \left( {\frac{{d_{\text{p}} }}{2}} \right), (2)$$

where \(u_{\text{p}}\) is the inclusion velocity (m/s), \(d_{\text{p}}\) is the inclusion diameter (m), \(\rho_{\text{f}}\) and \(\rho_{\text{p}}\) are the densities of fluid and inclusion (kg/m3), \(\mu\) is the absolute fluid viscosity [kg/(m s)]. Singh [13] proposed that the necessary initial inclusion velocity \(u_{\text{p}}\) should be 162 m/s for a 2-μ m inclusion crosses a 20-μ m boundary layer. Obviously, it is impossible for the inclusions in the nozzle, and small inclusions are seldom observed in the inclusion buildup without ECP treatment (Fig. 4a-c). Assume that the initial velocity of an inclusion is 1 m/s, and the smallest grain size should be 22.6 μ m to cross through the boundary layer by calculation. So, it can be seen lots of large inclusion in the inclusion buildup (Fig. 4a-c).

| Fig. 5 Schematic of inclusions movement close to the inner wall of SEN without a and with b ECP treatment |

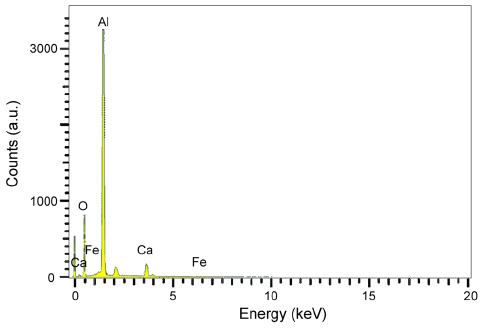

Certainly, the movement of the inclusions closing to the inner wall of ECP-treated SEN has some difference from that without ECP treatment. As revealed by the EDS (Fig. 6), the element of calcium was existed in inclusions besides aluminum and oxygen. Hence, it can be deduced out that calcia-alumina composites might be formed on the surface of some of alumina inclusions during the refining process. Namely, amorphous nonstoichiometric layers compose of calcia and alumina on the surface of these alumina inclusions. So, the surface layer possesses high-density vacancies at high temperature. Under the effect of ECP, charges are accumulated in the layers[14, 15]. That is to say, the vibration of inclusions, especially small size inclusions, should be enhanced by the electric field caused by ECP. Consequently, the initial inclusion velocity \(u_{\text{p}}\) of these inclusions is increased. As shown in Fig. 5b, lots of inclusions cross through the boundary layer and deposit on the inner wall of the ECP-treated SEN. Hence, small size inclusions are decreased in the ECP-treated slab (Fig. 2).

| Fig. 6 EDS result of the point denoted by P in Fig. 4f |

Moreover, as proposed by Bazant et al. [16], the outer layer of the inclusions can be changed by the effect of ECP, and the inclusions in molten steel are inevitably deflected along the direction of ECP. As a result, the inclusions are orderly piled up along the direction of ECP (Fig. 4f). In addition, because of the increase in element transport across grain boundaries caused by the ECP [17], the deposited inclusions are easily sintered to form dense inclusion buildup.

In summary, the application of low-density ECP on SEN can expel inclusions crossing the boundary layer along the current direction and significantly increase the density of the inclusion buildup. The mechanism analysis reveals that the amorphous nonstoichiometric layers with high-density vacancies are formed on the surface of some inclusions is ascribed to the improvement in the transport of inclusions, and the increase in element transport across grain boundaries caused by the ECP is ascribed to the densification of the inclusion buildup. Hence, the applying of ECP on SEN is beneficial to form dense inclusion buildup and expected to not only prolong the service life of SEN, but also improve the quality of the steel product.

This work was financially supported by the National Natural Science Foundation of China (No. 51304039), the Fundamental Research Funds for the Central Universities (Nos. N110402008 and N130402021), and Meishan Steel Plant Research Fund. The authors acknowledge the help of Prof. Z. S. Zou of Northeastern University for the valuable advice

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|