Molecular dynamics simulation is employed to study the tension and compression deformation behaviors of magnesium single crystals with different orientations. The angle between the loading axis and the basal < a> direction ranges from 0° to 90°. The simulation results show that the initial defects usually nucleate at free surfaces, but the initial plastic deformation and the subsequent microstructural evolutions are various due to different loading directions. The tension simulations exhibit the deformation mechanisms of twinning, slip, crystallographic reorientation and basal/prismatic transformation. The twinning, crystallographic reorientation and basal/prismatic transformation can only appear in the crystal model loaded along or near the a-axis or c-axis. For the compression simulations, the basal, prismatic and pyramidal slips are responsible for the initial plasticity, and no twinning is observed. Moreover, the plastic deformation models affect the yield strengths for the samples with different orientations. The maximum yield stresses for the samples loaded along the c-axis or a-axis are much higher than those loaded in other directions.

It is well known that the plastic deformation mechanisms of metal materials are related to the sample size [1, 2, 3, 4], temperature [5, 6, 7] and strain rate [8, 9, 10, 11] in addition to the intrinsic factors. In particular, the mechanical behavior dominated by orientation effect has attracted increasing attention in recent years [1, 12, 13, 14, 15, 16]. For example, Battaini et al. [15] have reported the effect of the sample orientation on the mechanical properties of commercially pure titanium plate with a transverse split basal texture at room temperature, and a large variation in the flow stress was found due to the sample’ s orientations. The deformation mechanisms of nickel single crystals have been studied by Li et al. [4] via atomistic simulations, which were characterized by massive dislocation activities within a single slip system and a nanoscale deformation twining in an octal slip system. Furthermore, Kim et al. [12] showed that the crystallographic orientation and the sample size are the important elements on tension-compression asymmetry in molybdenum nano-pillars. More recently, Xu et al. [1] explored the effects of the orientation, size and dislocation confinement on the plastic deformation of aluminum nano-pillars, which showed a significant dependence of the dislocation starvation state and the serrated stress-strain response on higher and lower symmetry orientations.

Due to the excellent properties of low density and high strength, magnesium and its alloys have been widely used in aerospace, electronics, mechanical industry and clinical medicine. However, for hexagonal close-packed (hcp) metals, the plasticity is poor owing to the limited slip systems. The orientation effect is a very important factor for deformation behavior to such asymmetric structure. For exploring the deformation mechanisms in magnesium, the compression experiments along c-axis have attracted wide attention [17, 18, 19, 20] and the loadings on the orientations are also concerned in recent published works [20, 21, 22]. Recently, uniaxial nano-compression experiments of Mg and Mg-0.2 wt% Ce pillars with the basal plane oriented 30° to the loading axis displayed the basal plane sliding and extension twinning [22]. In fact, deformation studies of magnesium single crystals have been conducted by using channel-die tests at room temperature since 1968 [17, 23], which revealed that magnesium exhibited the complex deformation behaviors and various deformation modes. Graff et al. [24] simulated the deformation mechanisms of magnesium alloy by finite element simulation, which matched the above channel-die test results [17, 23]. Moreover, the deformation behaviors of magnesium single crystals with five different orientations at fixed nominal column were presented by micro-compression experiments and display the orientation-dependent mechanisms of deformation at the nanoscale [25].

To better understand the plastic deformation behaviors and mechanisms of magnesium and its alloys, atomistic simulations have been employed widely [6, 26, 27, 28]. However, for the molecular dynamic simulations, researches are mostly focused on the deformation behaviors along some specific loading orientations, especially along the c-axis or a-axis. For example, Li et al. [27] studied the twin boundary interfacial structure and the configuration of zonal twinning dislocations for {10

Here, molecular dynamics simulations are applied to study the tension and compression deformation of magnesium single-crystal nano-pillars with different loading directions. Various initial plastic deformation mechanisms and subsequent microstructure evolution are analyzed and discussed in detail. This work provides a more deep understanding of the competition mechanism of different plastic deformations in magnesium single crystals with different orientations.

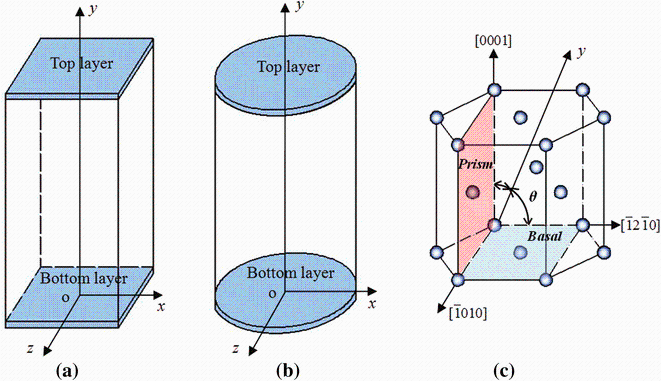

Two perfect single-crystal nano-pillar models with square and circular cross sections (Fig. 1a, b) were established, and the side length and diameter of the samples are about 14.3 and 14.6 nm, respectively. The height-to-side ratio for the square model and length-to-diameter ratio for cylindrical model were both about 2:1. The number of atoms in these two systems was about 280, 000 and 200, 000, respectively. Free boundary conditions were applied in x, y and z directions in simulations. Figure 1c shows a unit cell of the hcp lattice. For the samples with different orientation, the crystal rotated around the [

In the simulation, the perfect crystal was relaxed for 30 ps (5000 time steps) at zero force to minimize the potential energy at first. After that, a uniaxial loading was exerted along the y direction by applying a constant strain of about 5 × 107 s-1 on the 1.5-nm-thick top layer, while the 1.5-nm-thick bottom layer was fixed. Then, the system was relaxed for 6 ps before the next increment in tensional/compressive displacement was applied. The simulation was carried out until the maximal strain reached about 10% because the initial plastic mechanism was our concern in this work.

Based on the Liu’ s EAM potential, the initial plastic deformation mechanisms of the magnesium single crystals with different orientations under tension and compression are calculated and then listed in Table 1. The results are obtained in the strain range of 0.2% over the yield point. For the square nano-pillars in tension simulations, the first nucleated defects are, respectively, the {10

| Table 1 Initial plastic deformation mechanisms of the samples with different orientation θ under tension and compression |

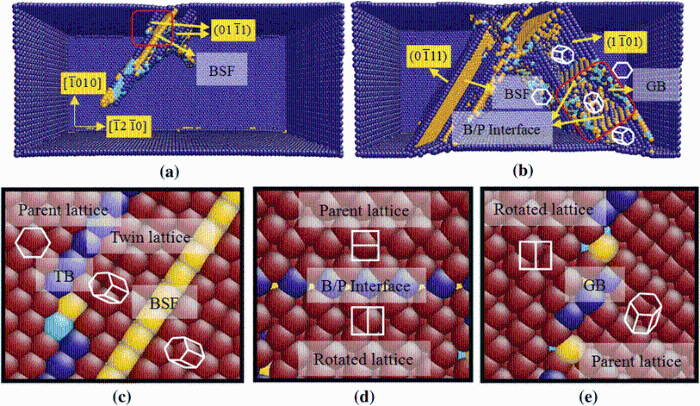

(1)θ = 0° : Fig. 2 shows the microstructural evolution of the [

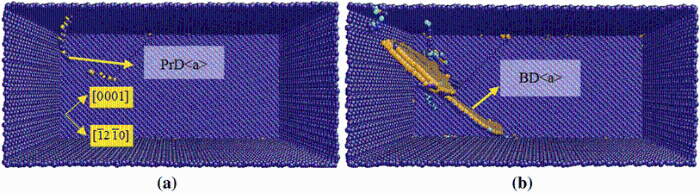

(2)θ = 20° : The plastic deformation occurs when the strain is up to 6.1% at θ = 20° , and a prismatic < a> dislocation loop nucleates at the free surface preferentially, as shown in Fig. 3a. Subsequently, Fig. 3b reveals that {10

(3)θ = 31.6° /45° : When θ is up to 31.6° and 45° , the Schmid factors of the basal (0001) [

| Fig. 4 Initial deformation mechanism of the circle column viewed along the loading y direction at θ = 45° with the strains of 5.5% a, 5.59% b, and 5.68% c |

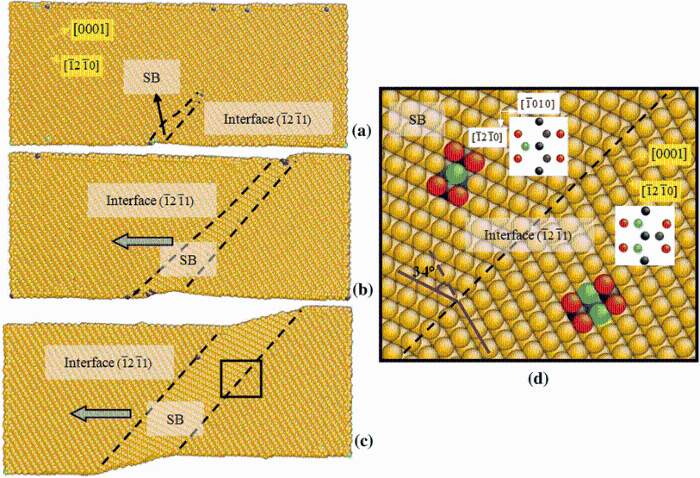

(4)θ = 58.4° /75° /80° : Fig. 6 shows the initial plastic deformation of the square column sample at θ = 58.4° . When the applied strain is up to 5.2%, a shear band (SB) appears at the free surface caused by the {

| Fig. 6 Initial deformation mechanism of square column under tension at θ = 58.4° with the strains of 5.2% a, b and 5.3% c. d Magnified figure of the shear band |

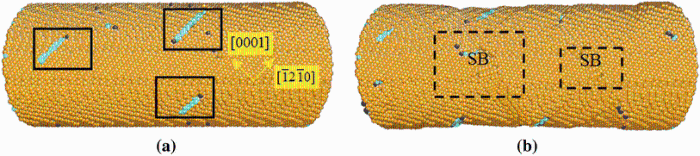

For the square column sample, the deformation mechanisms at θ = 75° and θ = 80° are similar as that of 58.4° , so they are not shown in detail here. However, for the cylindrical column sample, the results show a slight difference. When θ = 58.4° , the basal < a> dislocation is prior to nucleate at the surface which is marked as light blue in Fig. 7a. And the pyramidal shear band, which is similar to the structure in Fig. 6d, propagates with the increase in the strain (Fig. 7b). With the increase in θ , the basal slip is restrained. Whenθ is up to 75° , the pyramidal shear band appears prior to the basal slip. Further increasing θ to 80° , the pyramidal shear band is an only way for deformation, which is exactly consistent with the result of the square column. We suppose that the appearance of the basal < a> dislocation ahead of the pyramidal shear band is caused by the existence of the uneven surface for the cylindrical column models.

| Fig. 7 Initial deformation mechanism of circle column under tension at θ = 58.4° . a The prior defect of basal < a> dislocation. b The following defect of shear band |

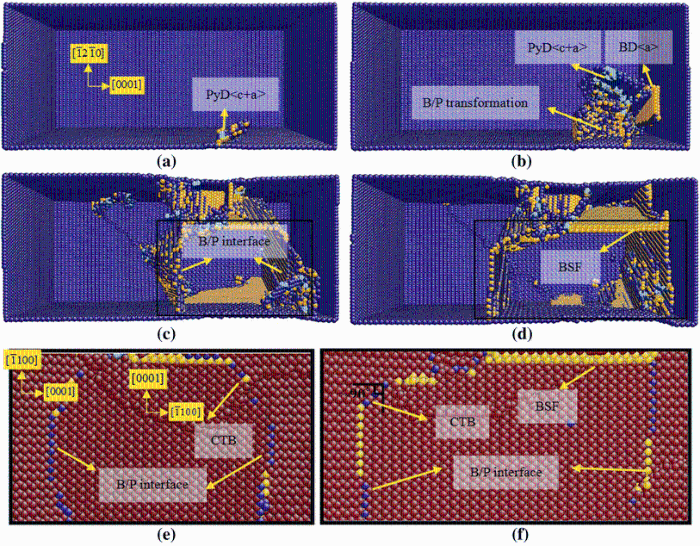

(5) θ = 90° : Under tensile loading along c-axis, in addition to pyramidal dislocations, the basal/prismatic (B/P) transformation is the main plastic deformation mechanism. Figure 8a-d show that the pyramidal dislocation is prior to occur in the stage of plastic flow, and soon the B/P transformation and the basal slip follow. Figure 8e and f exhibits the magnified atom configurations of B/P transformation. The B/P interface will run through the cross section and extend toward the terminal of crystal model by shuffling. Meanwhile, the basal stacking fault (BSF) also appears (Fig. 8d). The {10

According to previous experimental and simulated results [6, 26, 46, 47], the {10

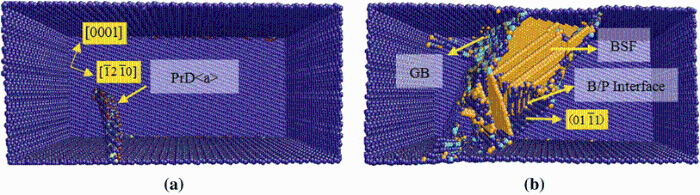

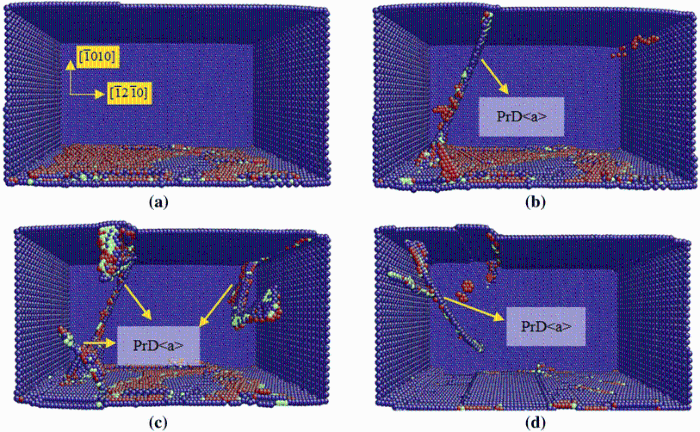

(1) θ = 0° : Fig. 9 shows snapshots of the deformation process of the [

| Fig. 9 Microstructure evolutions of the [ |

(2) θ = 10° /15° /20° : The deformation mechanisms under compression at θ = 10° -20° are consistent with those at θ = 58.4° under tension that the main deformation was dominated by SB. Taking the compression simulation of θ = 20° with the strain up to 4.8% as an example, the SB occurs with a rotation of 34° due to {

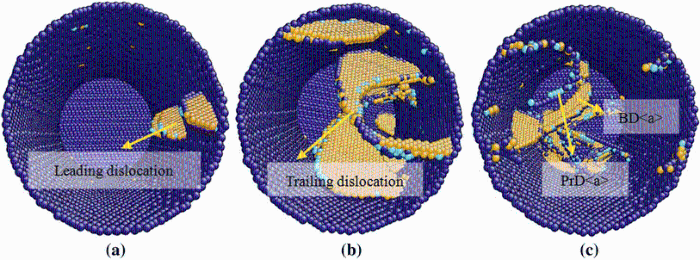

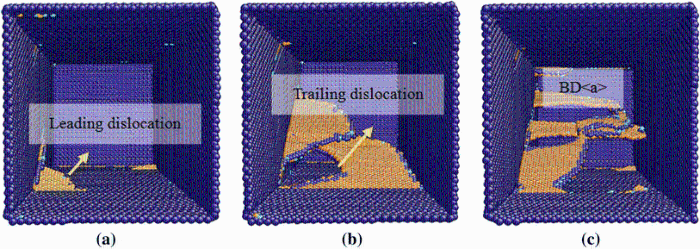

(3)θ = 31.6° /45° /58.4° : As expected, the basal slip is main contribution to the strain accommodation due to the high Schmid factor and low critical resolved shear stress (CRSS) in the θ range from 20° to 75° . The slip plane is clearly presented by the yellow atoms in Fig. 10. At the plastic stage, the leading partial dislocation in basal plane starts and the stacking fault follows, as shown in Fig. 10a. Then, the trailing partial basal dislocation appears in Fig. 10b. With the increase in the strain, more basal < a> dislocations appear as shown in Fig. 10c.

| Fig. 10 Microstructure evolutions of the square column under compression at θ = 31.6° |

(4) θ = 75° /80° /90° : When compression loading is applied near or along the c-axis, the main mechanism of plastic deformation is pyramidal and subsequent basal slips which are coincident with the previous simulation results of c-axis compression presented by Guo et al. [30]. Their results also revealed that a leading partial pyramidal dislocation nucleated at the free surface, and then, a trailing partial pyramidal dislocation followed successively, which leads to a perfect {10

In order to comprehensively evaluate deformation mechanism for magnesium single crystal, more extensive simulations and comparisons are imperative by using the empirical potentials. Therefore, Sun’ s EAM potential [35] was introduced in our calculation for the same simulation models. Compared with the incipient deformation modes which were simulated by Liu’ s EAM, most of the simulation results calculated by Sun’ s EAM potential are similar. Only a small portion of results have shown a slight difference, which may be attributed that the prismatic < a> dislocation is not easy to nucleate, while the basal < a> dislocation behaves more actively. For instance, no prismatic < a> dislocations appear in tension simulations when θ is 15° -20° , and only {10

To make our simulation results more convincible and reliable, several published experimental results of magnesium as the comparison to our simulation have been surveyed in following. For the case of experimental results, uniaxial micro-compressions of magnesium single crystal along [0001], [2

Based on the simulated and experimental results, it can be concluded that when the loading is applied at the direction of around 45° from c-axis or a-axis, the basal dislocation dominates the initial plasticity due to the high Schmid factor and low critical resolved shear stress (CRSS). In our simulations, the prismatic slip is also observed under the tension along the loading axis of about 45° which may be caused by the free surface and the nano-size effect. When the loading is applied near c-axis or a-axis, the basal slip is restricted; thus, pyramidal slips, twinning, crystal reorientation and B/P transformation occur. In the a-axis compression, the prismatic slip dominates the initial plastic deformation because some prismatic planes of magnesium single crystal are in the preferred slip directions, which are not perpendicular or parallel to the loading direction. Besides, it is noticed that the twinning, crystal reorientation and basal/prismatic transformation only appear in the crystal model loaded along or near the a-axis or c-axis. It means that the twinning, crystal reorientation and basal/prismatic transformation are not easy to active compared with the basal and prismatic slips. Thus, they can only occur when the basal and prismatic slips are restricted.

It is well known that the initial deformation mechanism has a predominant influence on the maximum yield stress (σ max), which may vary with different crystallographic orientations and loadings. In Table 2, σ maxand the initial deformation mechanisms with different orientations under tension and compression are listed. In the tension simulations, the lowest σ max values (about 1.6 GPa) correspond to θ = 0° -10° , while the simultaneous initial defects of {10

| Table 2 Initial defects and maximum yield stresses (σ max) with different orientations under the tension and compression |

Furthermore, due to different plastic deformation mechanisms under the tension and compression, the maximum tension yield stress (σ max-t) and compression yield stress (σ max-c) are different. We can see that σ max-t is lower than σ max-c when θ is less than 31.6° , and σ max-t exceeds σ max-c when θ is in the range of 31.6° -58.4° . Therefore, the values of the tension and compression strengths strongly depend on the loading orientation. Therefore, it is well to say that σ max-t and σ max-c near c-axis and σ max-c at a-axis are much bigger than the loading in other directions.

Molecular dynamics simulations were used to study the tension and compression behaviors of magnesium single crystals with different orientations. For ten different orientations with the angles ranging from 0° to 90° , different plastic deformation mechanisms are observed. For both tension and compression, when the loading is applied at the directions of around 45° from c-axis or a-axis, the basal dislocation dominates the initial plasticity due to the high Schmid factor and low CRSS. When the loading is applied near c-axis or a-axis, the basal slip is restricted; thus, the pyramidal slips, twinning, crystal reorientation and B/P transformation occur. Both B/P interface and CTB appear under c-axis tension, while the CTB always connect the B/P interface. Besides, the B/P interfaces are also observed under a-axis tension accompanying the crystal reorientation. In compression simulations with different orientations, the basal, prismatic and pyramidal slips dominate the plastic deformation. No twins participate in the deformation, although the twin-like shear bands caused by the {11

This work was financially supported by the National Natural Science Foundation of China (No. 11372032) and The Open Project of Key Laboratory of Computational Physics in China.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|