Three-dimensional morphology and formation process of icosahedral quasicrystal phase have been investigated in a melt-spun Al-18Mn alloy (in wt%). Three distinct layers corresponding to varying temperature gradient have been observed on the cross section of the ribbons. 3D morphologies of cellular and dendritic icosahedral phase have been obtained through electro-etching. A model has been proposed to describe the formation process of the icosahedral phase and α-Al during the rapid solidification. The icosahedral phases are primarily precipitated from the melt into fine cellular and dendritic particles, and subsequently engulfed by the α-Al which propagates in a planar morphology.

The initial study of icosahedral quasicrystal phase (I-phase) in the rapidly solidified Al86Mn14 alloy [1] heralds the discovery of a new structure that is neither amorphous nor crystalline [2]. Then, many other I-phases that exhibit similar structure have been found in the aluminum alloys and other alloys [3, 4, 5, 6, 7, 8]. Quasicrystal has already exhibited several engineering applications such as the strengthening phase in the metal-matrix composite [9, 10]. The mechanical properties of the metal-matrix composites are dependent on the morphology, volume fraction, and distribution of strengthening particles; therefore, a comprehensive microstructural characterization of I-phase is critical for understanding the mechanical performance of the quasicrystal-reinforced metal-matrix composite [4, 11, 12, 13].

The equilibrium shape of a crystalline phase is often determined by surface energy, which is intrinsically related to the atomic configuration. However, for the I-phase, the shape is far more complicated, owing to their lack of translational periodicity [14]. Furthermore, the shape of the I-phase is susceptible to the cooling rate and composition [15], which increases the challenges for microstructural characterization. Even for the most extensively studied Al-Mn alloy, in spite of substantial experimental observations on the dendritic and spherical I-phase [16, 17, 18], the intrinsic law that governs the morphological characters during the rapid solidification has not been fully revealed.

To determine the relationship between the microstructural character of I-phase and the solidification process, a melt-spun Al-18Mn alloy (in wt%) has been investigated. This paper concludes that icosahedral phases are primarily precipitated from the melt into fine cellular and dendritic particles, and subsequently engulfed by the α -Al with a planar morphology.

Al-18Mn master ingot was prepared by induction melting of pure Al (99.9%) and Mn (99.9%) under an argon atmosphere. Ribbons were obtained by spun the molten of master alloy onto a rotating copper wheel, which rotated at a linear velocity of 52.3 m/s. The ribbons were typically 40 μ m in thickness and 8 mm in width.

The cross section was processed following the standard mechanical metallographic procedure (grinding and polishing). The microstructure of the cross section was characterized by scanning electron microscope (FEI Quanta 200FEG) attached with an energy-dispersive spectroscopy (EDS). Icosahedral quasicrystal phase was identified using transmission electron microscopy operated at 300 kV (TEM-TECNAI F30). The TEM samples were prepared by slicing several wafers from the directional solidification specimen perpendicular to the growth direction. A Gatan 659 disk punch was then used to cut into 3-mm-diameter disks from the thin wafer. Subsequently, the disk was mechanically ground to a thickness of ~50 μ m, and the resulting foil further thinned by a Gatan 691 precision ion polishing system until transparency at the center of the specimen was achieved. The ribbons were electro-etched in a 250 mL 2 wt% KI methyl alcohol solution to reveal the 3D morphology of I-phase. The voltage, temperature, and current density for electrolytic etching are 10 V, 25 ° C, and 0.1 A/cm2, respectively.

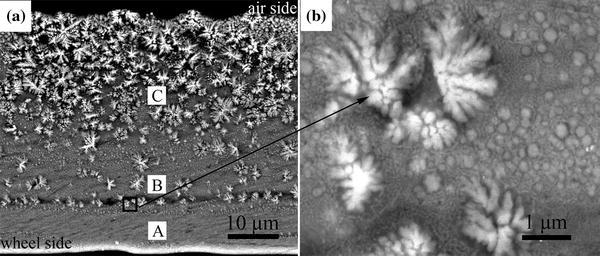

Figure 1a shows the cross section of the ribbon, where a progressive microstructure variation with the distance from the cooling substrate can be observed. Three distinct layers can be identified through the whole cross section, marked as A, B, and C. Region A is in the vicinity of the copper wheel and subjects to the largest cooling rate, and the microstructure is composed of rather uniform distributed tiny spherical quasicrystalline particles with sizes of a few tens of nanometers in an α -Al matrix, which is similar to the result of Boncina in melt-spin Al-Mn-Be alloy [19]. Region B features the emergence of fine cellular particles with a few dendrites. In region C, which is furthest from the cooling substrate, the microstructure is composed of coarse dendrites (about 5-10 μ m). According to the XRD pattern in Fig.2, only α -Al and I-phase peaks can be identified. EDS results show that the dendrites and cells have significant Mn concentration. Therefore, the discernible dendrites and cells in Fig.1a are all I-phases. Figure 1b is the magnified image of the interface between regions A and B, where a group of fine cellular I-phases with a few randomly distributed dendritic I-phases can be observed.

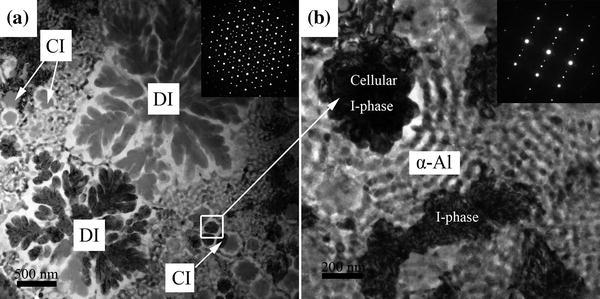

Figure 3a shows the bright-field image of the longitudinal section for melt-spun Al-18Mn alloy. The microstructure has a marked resemblance with that in Fig.1b. I-phase exhibits two distinct types of morphology, namely dendritic (DI) and cellular (CI). The dendrites stem from a center core and grow radially outward, and the selected area electron diffraction (SAED) of the dendritic I-phase exhibits a perfect fivefold symmetry, as shown in the insert in Fig.3a. Figure 3b is the magnified image of a cellular I-phase, and the SAED of this cellular I-phase exhibits a mirror feature, which is also typical for the icosahedral phase found in the Al-Mn alloy [20]. The cellular I-phase in Fig.3b is surrounded by the band-like α -Al matrix.

| Fig.3 a TEM micrograph of as-spun ribbon showing dendritic I-phase (DI) and cellular I-phase (CI); b magnified image of the square area in a |

The 3D morphology of the I-phase is obtained by isolating the I-phase from the surrounded Al matrix. The morphological features of a cellular and a dendritic I-phase are shown in Fig.4a, b, respectively. The surface of this cellular I-phase is not perfectly smooth, but filled with irregular grooves. I-phase dendrites have elongated dendritic arms stem from a center core and grow radially outward. The length of a single dendritic arm is about 3 μ m, which is in good agreement with the I-phase dendrites shown in Fig.3a.

According to the EDS results, chemical composition through the regions A and B of the melt-spun ribbon is homogeneous and equals to the master alloy (Al-18Mn). However, the maximum solubility of Mn in Al is about 15 wt% under rapid solidification [21]. Therefore, there is a complete solute trapping in regions A and B. The microstructure variation observed in Fig.1a can be ascribed to different cooling rates [22]. In the region A, the heat is dissipated directly through the conduction with the cooling substrate, leading to a largest cooling rate. For regions B and C, however, the cooling rate is significantly lowered due to the less effective heat dissipation and the release of the latent heat.

It has been well established that the interfacial energy between I-phase and the undercooled liquid is very small [23], so the activation energy required to form a critical I-phase nuclei is reduced, and the formation of the I-phase is favored over the competing crystalline phases as less atomic reconstruction is required [24]. The nuclei of the I-phase are assumed to form directly from the preexisting icosahedral structure in the undercooled liquid [25], as schematically illustrated in the Fig.5a. During the initial solidification, the shape of I-phase is almost tiny sphere near the cooling substrate region, where the cooling rate is so large that the I-phase grows in a planar morphology. When the cooling rate is slightly reduced, a large number of cellular I-phases appear along the S/L interface. Those fine cellular I-phases are assumed to arising from the liquid droplets preserved after the collapse of the cell grooves of Al [26] and then engulfed by the solidification of the Al matrix. This process is best illustrated by the cellular I-phase trapped in an α -Al matrix, as shown in Fig.3b. The release of the latent heat during solidification promotes the growth of the cellular I-phases into fine dendrites. The primary formation of I-phase is also confirmed by the unconstrained dendritic morphology of the I-phase, as shown in Fig.4b. This process is illustrated in Fig.5b. For a single I-phase dendrite, the average Mn concentration is about 31.6 wt%, which is significantly higher than the master alloy. Considering the low diffusivity of Mn atoms, Mn atoms are not likely to diffuse a long distance during the rapid solidification process, and further growth of I-phase may be suppressed until the cooling rate is reduced, leading to the formation of α -Al, as shown in Fig.5c. Unlike the radial growth of α -Al found in the rapidly solidified Al-5Co alloy (in wt%) [27], α -Al in the rapidly solidified Al-18Mn alloy exhibits a uniform distributed microstructure, as shown in the Fig.3b. So it can be concluded that the α -Al phase propagates with planar interface morphology and engulfs the earlier solidified I-phase. The growth process of I-phase is schematically shown in Fig.5.

In summary, the present work has investigated the 2D and 3D morphologies of I-phase obtained in melt-spun Al-18Mn alloy. Three distinct layers have been observed on the cross section of ribbon. The 3D morphologies of cellular and dendritic I-phases are presented and compared with 2D counterparts. A model has been proposed to describe the growth process of the icosahedral phase and α -Al during the rapid solidification. The icosahedral phases are primarily precipitated from the melt into fine cellular and dendritic particles, and subsequently engulfed by the α -Al in a planar morphology.

This work was financially supported by the National Natural Science Foundation of China (Nos. 51274054, U1332115, 51401044), the Keygrant Project of Chinese Ministry of Education (No. 313011), the Science and Technology Planning Project of Dalian (No. 2013A16GX110), and the China Postdoctoral Science Foundation (No. 2015T80248).

The authors have declared that no competing interests exist.

作者声明: 无竞争性利益关系

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|